API 6A

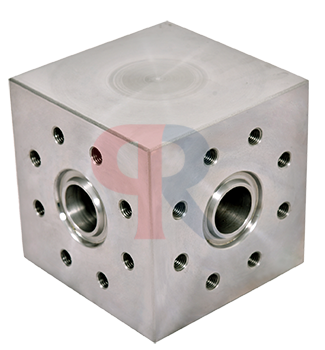

STUDDED CROSS

Prithviraj Industries manufactures API Specification 6A Crosses and Tees with studded connections in all API 6A sizes and pressure classes. These products are manufactured in accordance with the dimensions and design criteria specified in API Specification 6A.

KEY FEATURES

- Designed according to the standards and tables in API Specification 6A.

- Can be designed in any combination of sizes and connections.

- Available for all API rated working pressures.

- Available with Stainless Steel 3 l 6L or lnconel 625 corrosion resistant alloy ring grooves.

- Normally provided with tap end studs and nuts.

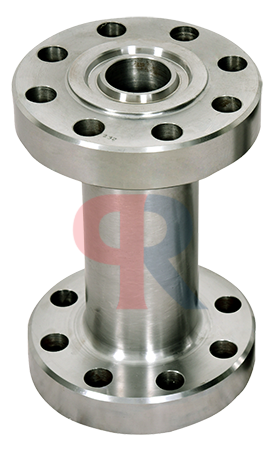

ADAPTER AND SPACER SPOOLS

Prithviraj Industries manufactures Spacer Spool with a variety of end and outlet configurations based on customer needs.

KEY FEATURES

- Flanged and Studded ends available, in any combination.

- Manufactured for any combination of size and pressure ratings.

- Spacer Spools are designed to minimize length while allowing sufficient clearance for wrenches or clamps, unless otherwise specified by the customer.

- The standard design for Spacer Spools does not include outlets, although outlets can be added as specified.

- Available for general services and sour services in compliance with any temperature rating and material requirements specified in API specification 6A.

- Available with Stainless Steel 316L or lnconel 625 corrosion resistant alloy ring grooves.

- Tap-end studs and nuts are normally provided with studded end connections.

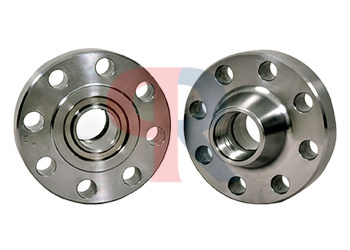

API FLANGES

Prithviraj Industries manufactures 6B and 6BX flanges in various sizes & pressure ratings as per API 6A. Most common material is low alloy steel AISI 4130. AISI 410 or UNS 31803 which are used for some of the critical services. Application of CRA (SS 316 or Nickel alloy 625) enhance the corrosion resistance ability of ring groove, thus enhancing the product life.

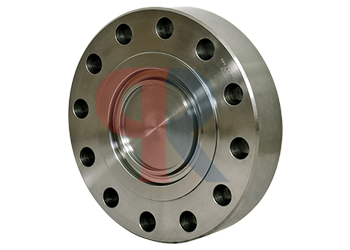

6BX FLANGES

6BX flanges are ringjoint type and has a raised face. Joining make-up bolting force acts on the raised face of the flange when the gasket is properly seated. This support prevents damage to the flange or gasket from excessive bolt torque. Therefore 6BX connection has raised face. Type 6BX flanges are of through bolted or studded design. Face-to-face contact is not necessary for the proper functioning of the 6BX flange. 6BX flanges have BX ring gasket groove.

TYPES OF 6BX FLANGES ARE:

- Welding Neck Flanges

- Blind Flanges

- Threaded Flanges

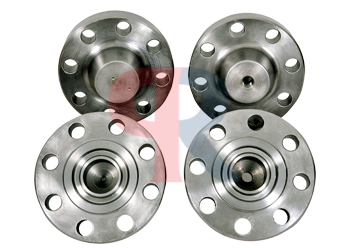

6B FLANGES

6B flanges are ring joint type and are not designed for face-to-face make-up. Bolting force acts on the metallic ring gasket. 6B flanges are of through bolted or studded design. R or RX are ring groove type.

TYPES OF 6B FLANGES ARE:

- Welding Neck Flanges

- Blind Flanges

- Threaded Flanges

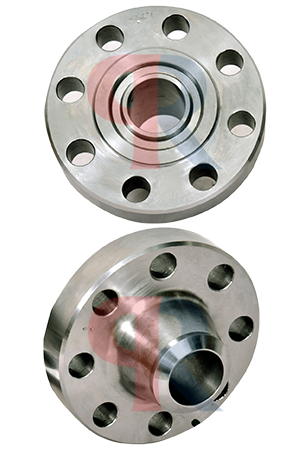

WELD NECK FLANGE

Our Weld Neck Flanges feature high strength, good toughness and high resistance to corrosion, high pressure and temperature. Can be customized to meet specific requirements with different buttweld end sizes and a range of material of construction with options to meet Nace MR-0175. The Ring grooves can be reinforced with Inlay SS / Inconel to inhibit corrosion in Carbon and low alloy steels.

KEY FEATURES

- This is most common type of high pressure pipe flange. They are distinguished f om other type of pipe flanges by their long tapered hub and gentle transition of thickness in the region of the buttweld joining them to the pipe. The long tapered hub provides an important reinforcement of the weld neck flange proper in terms of strength and resistance to dishing.

- Wide range of selection for material and Specifications, (API, ANSI, MSS, etc.)

BULL PLUGS

Bull Plugs are threaded nipple with a rounded, closed end used to stop up a hole or close off the end of a line. Pressure-containing closer for a female threaded and or outlet connection which may have an internal counter bore and/or test port. The Material & Design of Bull Plugs are determined with the working pressure and external load capacity. Bull Plug material as a minimum meets the requirement of PSL 3 material in accordance with material designation 60K for 13.8 MPA to 69 MPA working pressure. The material requirement of Bull Plug shall be for sour services (DD, FF or HH). Bull Plug conforms to the dimension and tolerance for NPT Size 4 Inch & Larger inline pipe size.

VALVE REMOVAL PLUGS

Valve Removal Plugs are threaded plugs that can be installed in the wellhead to enable gate-valve removal under pressure. Valve Removal Plug material as a minimum meets the requirement of PSL3. Material is in accordance with material designation 60K for 13.8 MPA to 69 MPA working pressure & 75k for 103.5 MPA to 138 MPA working pressure The material requirement of Valve removal plugs shall be for sour services (DD. FF or HH). Valve removal plugs threads are coated to minimize galling and to develop maximum leak resistance. Valve Removal Plugs are not designed for use with test and blind flanges. There are 4 sizes and 2 pressure ratings available.

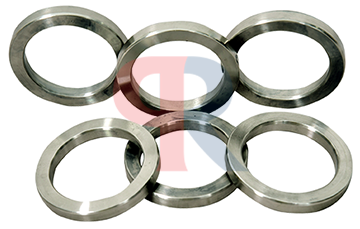

RING JOINT GASKET

Prithviraj Industries manufactures metallic Ring Joint Gaskets which are suitable for high pressure and high temperature applications. The Gaskets are available in R, RX, BX styles and in oval/octagonal profiles. In addition, these units are manufactured in accordance with specific tolerances on CNC machines.

Our Ring Joint Gaskets fully comply with the ASME B 16.20 standard and the API spec 6A requirements (wherever applicable).